By Paul Manning , Manager, dss+

An operations manager travelling away from her facility for a week knows that there are critical maintenance activities underway during the week involving live electrical works and confined space entries. There is always a level of unease with these activities underway and not being there to keep an eye on things. Coupled with a newly promoted and still learning new supervisor, use of a new contractor, and knowledge that the last audit exposed gaps in the completeness of the old paper-based Permits to Work forms that were missing job safety analyses for high risk activities, this can cause a lot of stress on the organization. But even with a level of unease that never goes away, the operations manager has a level of calm and confidence after checking the status of all permits via her smart phone and the new Permit to Work technology. With a quick review, she sees that the new contractor’s licenses are valid and a couple of them even reviewed the embedded micro learning videos on confined space entry., It was great to be able to open the job safety analysis that a second contractor had uploaded for the live electrical work and then ring the new supervisor to coach him on how to help the contractor make a few upgrades before the work starts. The technology doesn’t take away the risk, but the ability to get a quick live glimpse into the high-risk work underway does help to make sure that everyone goes home in one piece at the end of the day.

While organizations in Australia are making progress reducing workplace fatalities and injuries, they nevertheless are still occurring. Since 2007, organisations have reduced annual workplace fatalities by 41%. Still, 182 Australian workers lost their lives in 2017[¹]. In real terms, that means the number of fatalities have been falling each year by roughly 12, or about 5%. At this current rate of improvement, it can be inferred that 170 lives will be lost in 2018, or 14 per month. By early February 2018, 12 lives have already been lost, meaning that Australian industry is unfortunately on track to have the anticipated number of fatalities this year.

Additionally, the serious injury/illness rate is currently around 9.5 claims per 1000 employees, reduced reduction of only 29% in the 10 years from 2004/05 to 2014/15². This rate of improvement suggests that it would take another 15 years to arrive at zero serious injury/illness claims.

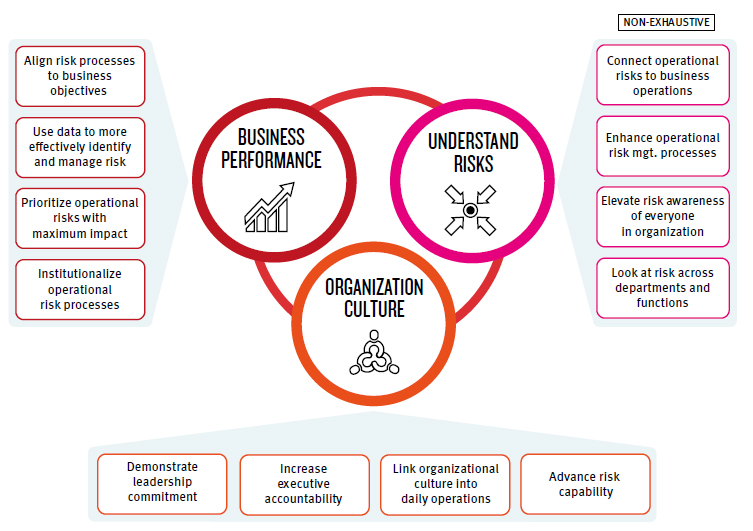

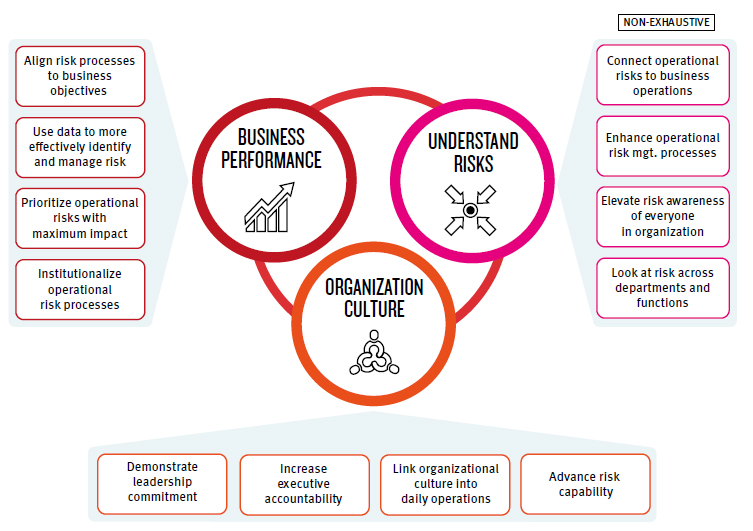

Of course, while achieving zero fatalities and serious injuries should be the goal of every organization, the reality is such an achievement is very difficult to obtain. Organizations must constantly grapple with how to manage risk in an integrated way to keep people safe and deliver business performance (Figure 1).

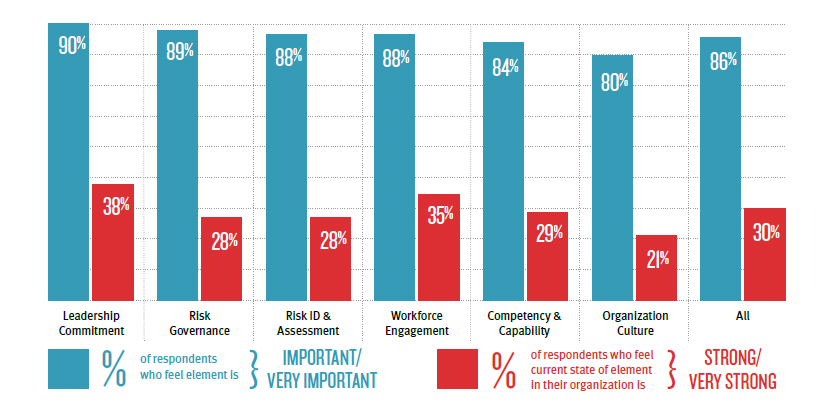

Figure 1 – Operational Risk Management

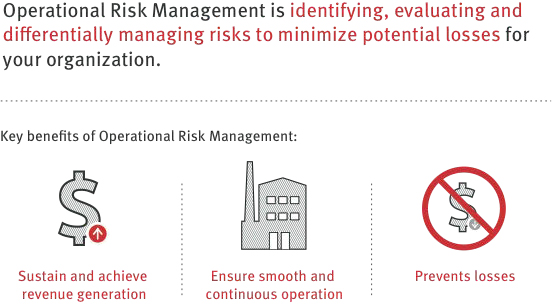

In 2017, dss+ conducted a global survey of high risk industries with the objective of gaining insight to help organizations reduce the impact of operational risk, and beyond that, turn the management of operational risks (as opposed to the management of external risks, which typically occupy the minds of executives) into a means of competitive advantage. The significant findings (detailed in Figure 2) of the survey include:

- Not enough resources & capabilities are being deployed to manage the risks that threaten right to operate;

- Significant disconnects and misalignment exist between leadership and employees, which greatly contributes to the likelihood of a catastrophic event; and,

- Three out of four respondents to the survey (75%) felt that their business performance management of operational risks was inadequate.

Figure 2 – The gap between what executive believe to be important compared with how well their organization manages each element.

These are alarming findings, to say the least, and they point to the imperative of developing new ways to better manage operational risk and prevent significant incidents that disrupt business, threaten right to operate and injure people, sometimes fatally. Failure to address these gaps will leave efforts by organizations plateaued when they need to be accelerating their rate of improvement.

A solution can be found through the effective use of emerging technology to achieve improved identification, evaluation and differential management of operational risks. Rapidly developing (and more user friendly) technologies and analysis capabilities can put richer insights into the hands of leaders, enabling them to make more integrated and informed decisions toward managing operations

risk.

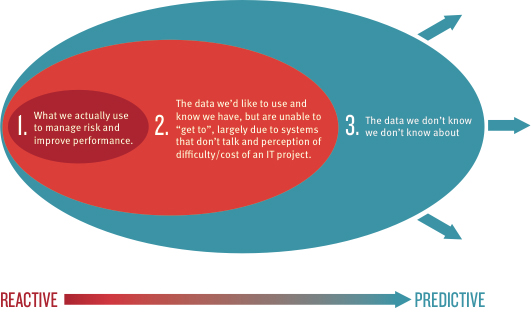

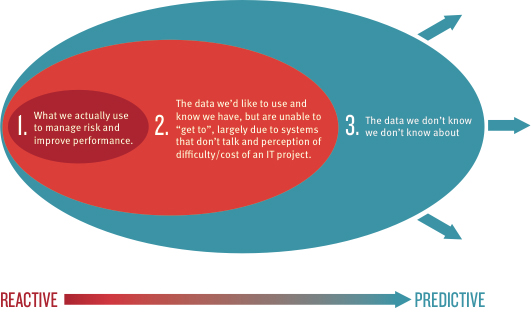

Businesses create massive volumes of data that is largely untapped, and in many cases unknown, that could be used towards predictive management of risk (Figure 3 – block 3). The current reality however is that this is an untapped mine of information with many businesses only using a limited set or metrics (Figure 3 block 1) and confounded by how to access the rest (Figure 3 block 2). Creating the capability to extracting leading insights from data allows leaders to make informed decisions and be more effective in leading improvement of systems and processes and people engagement.

Figure 3 –The mine of data that exists; 1) what is used today, 2) what a business knows it has but cannot access & 3) What businesses don’t even know they have or could access.

With new capabilities to capture, access and draw insights from data built on deep knowledge of global best practices, leaders can gain greater insights and understanding of what is happening within their organization. Technology that enables the connection of data from traditional enterprise systems (that don’t talk to one another), combined with analytics techniques to handle huge volumes of data, via a simple, easy-to-use platform with an intuitive user interface, allows access to insights that are relevant and really make a difference. And it can happen in real time. This information can help organizations ensure the right defenses are in place and working before incidents.

Historically, accessing and effectively utilizing this valuable data has been a struggle. This is primarily because most organizations typically only capture data on incidents that have happened and not the factors that lead to them. Even organizations that see the benefit of capturing a broader set of data are often frustrated by the lack of technical capability to capture essential data across various systems that are not integrated, making collation and analysis of the data required a serious IT challenge or manual effort that is prohibitively expensive.

Also, much data is collected in a superficial way through paper-based forms that is reliant on manual data entry. In many cases, this data is used only to demonstrate compliance with regulatory requirements and is rarely accessed to drive effective learning. The time it takes to enter and collect this information and analyze it renders the data nearly meaningless and makes the whole process very disengaging. Data that is captured often relies on Excel as the tool of choice for analysis. Oftentimes data captured via manual entry from paper forms is riddled with errors and omission, again making it very difficult to use, be trusted, or be viewed as value adding.

As shown in Figure 4, access to quality, trustworthy data in real time is a critical building block in an integrated approach to Operations Risk Management. It is very difficult to be truly proactive in the management of risk if the data being used is reactive and focused on things that have happened.

Figure 4 – Use of data is a key block of an integrated approach to sustainable business performance

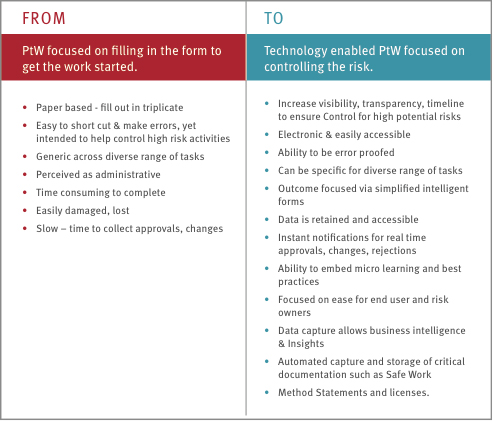

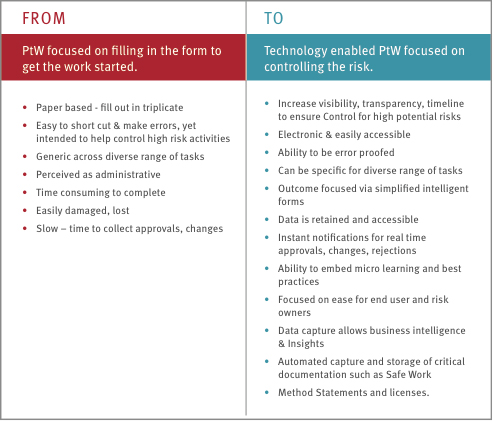

dss+ is working with a leading technology partner to digitally enable Operations Risk Management, leveraging the many advances being made in data capture (including Internet of Things) and devices to provide instant access that arm leaders with insights not achievable with via traditional systems and approaches. As the first step in what will be a scalable and integrated approach, the development is targeting Permit to Work. Why Permit to Work? Because it is an existing process common across industry as part of a Safety Management Systems to manage risks that are known to lead to both fatal and serious injury incidents. It is currently largely perceived as an administrative compliance driven requirement. Figure 5 highlights how technology is delivering advanced data capture, workflow management, reporting and analytics, enabling organizations to keep track of all open permits, workers who are on site, and all stages of workflow in real-time.

Figure 5 – Permit to Work – Technology Enabled Business Processes

The digital Permit to Work platform, delivered as a mobile app, is connecting stakeholders on any device (desktop, laptop, smartphones and tablets), at any site (including offline capability where a wireless or 3G/4G connection is not available). The forms and workflows can be customized at any time and distributed to users immediately, eliminating the need for IT projects to capture continuous improvements.

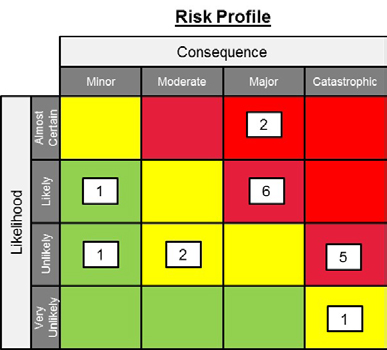

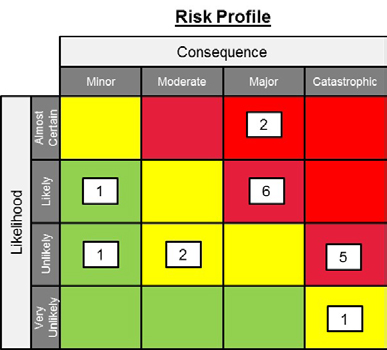

The potential to use new technology to manage Operations Risk and keep workers safe is tremendous and far beyond simply automating existing business processes. Imagine being able to have the risk profile (Figure 6) of your operation appear in real-time on your smart phone, integrated from your existing enterprise systems, giving you the insights you need to make decisions and take action that protects your people, your assets and the environment. The future is about the insights we can gain, the ability to quickly flex and adapt processes to accommodate business changes, lessons learned and new best practices. The goal is to enable organizations to accelerate reduction in serious incidents, better engage their people, and effectively manage risk in a sustainable and integrated way.

Figure 6: Risk Profile matrix example

Paul Manning is a Manager at dss+. dss+ is a leading provider of world-class operations consulting services to help organizations transform and optimize their processes, technologies and capabilities.

dss+ is committed to improving the safety, productivity and sustainability of organizations around the world.

Additional information is available at: www.consultdss.com.

- Safework Australia – Comparative Performance Monitoring Report 18th Edition – Work-related traumatic injury fatalities Australia 2016

- Safework Australia – Key Work Health and Safety Statistics Australia 2017