Risk-Based Approach Leveraging Digital Solutions: Using Video Analytics for Minimized Risks

The organization is one of India’s largest & global business conglomerates with a strong footprint across various sectors like steel, energy & infrastructure. Since 2012, dss+ has been working with the company to help improve its safety performance. In 2017, dss+ and the company started working on an initiative to identify key operations risks present across its manufacturing plants in various areas –

- People

- Process / Equipment / Materials

- Traffic / External Factors

To address some of the risks, the company had intended to keep a continuous monitoring system with minimal human intervention and high accuracy that can minimize human errors and automate risk identification. It invested in a video surveillance system and has a good infrastructure that can capture video data and store it. dss+ proposed leveraging the existing infrastructure to reduce risk, identify hazards and generate value by analyzing the live video feed coming from the vast network of cameras deployed across the plants.

Diagnostic Assessment

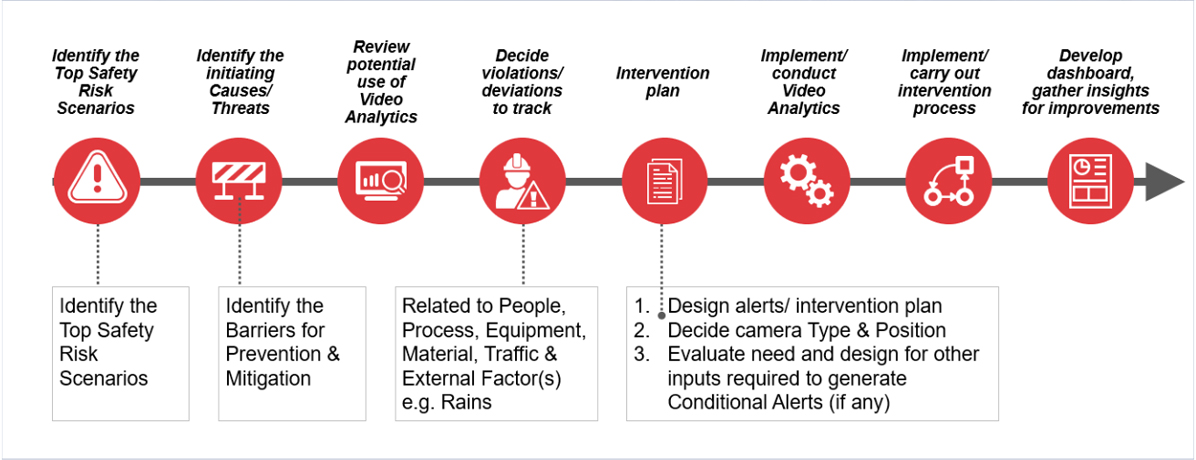

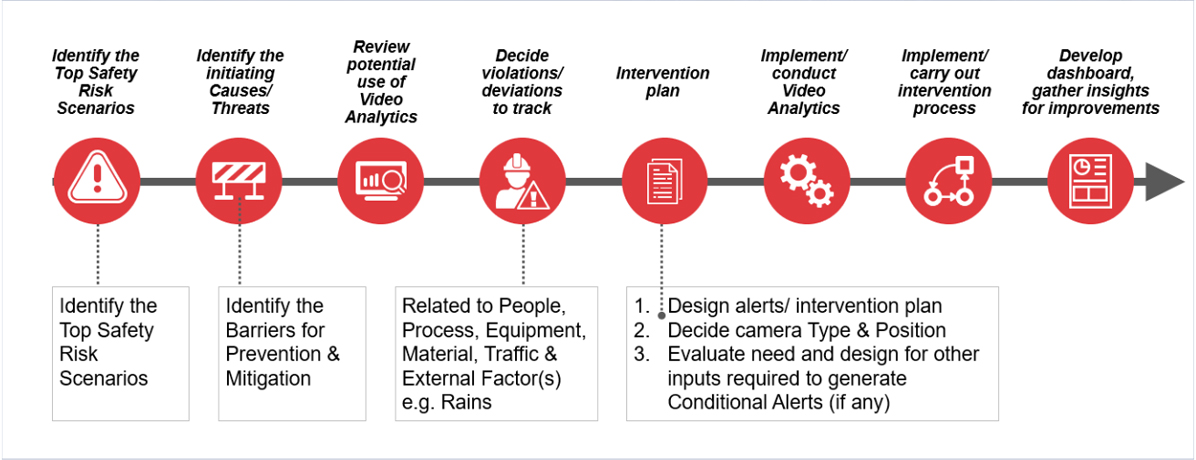

dss+ collaborated with the organization and used a risk-based approach for identifying the most critical scenarios by leveraging video analytics. During the thorough assessments at various sites, dss+ could spot high-risk activities such as working from heights, performing work at non-permitted zones, not following the standard protection guidelines, non-compliance with traffic regulations etc. As a first step, a pilot was conducted at the largest site to ensure there is a technical feasibility, scalability and capability to deliver on the use cases as a Proof of Concept (PoC). A risk-based approach to qualify high-risk scenarios was chosen and the roadmap of the PoC was planned as follows.

The PoC was carefully chosen to cover the most important risk scenarios for the company and the following key risk scenarios for real-time video analytics were identified –

1.Violation of safety procedures.

2.Traffic risks identification & conditional alert management.

3.Event based risk identification in regions of interest.

1.Violation of safety procedures

Identifying violation of safety procedures was demonstrated through a PPE violation detection at one of the construction sites. The workers violating the safety procedures related to PPE were identified and notified by a Point Turn Zoom (PTZ) camera feed analysis. The edge analytics, done on the edge box gave instantaneous results with least latency. The accuracy recorded was 95%.

2.Traffic Risks Identification & Conditional Alert Management

Using an existing camera setup that was deployed at the site, traffic risks were reported by identifying vehicles that were parked on the free left hand-side (wrong parking as per the site regulations). In addition, vehicles entering the no-vehicle zone were marked along with the nature of violation and timestamp.

3.Event-Based Risk Identification In Regions Of Interest

Notifications and alerts when personnel enter an unauthorized zone in a particular region of interest was an important use case for the client. As part of the PoC, dss+ leveraged an existing camera infrastructure within that region of interest. The personnel working at the zone and their positions were identified, marked and notified in case of a violation.

Overall, the proof of concept demonstrated the technical capabilities to identify the most important and complex event-based alerts for the client by leveraging the existing real-time video feed.

Next steps – Extend scope of Video Analytics to monitor various risks across the plant

As part of this investigation at the client’s sites, dss+ identified more than 20 key risks spanning people, processes / equipment / materials and traffic. Video analytics scope, as a part of the program, was:

- Monitor unsafe acts and procedures: Texting while walking, violations to safety procedures during working at heights, working at hazardous zones, wearing the wrong type of PPE for the job, etc.

- Access to ‘Red Zone’ (proximity) of a moving conveyor, or under a suspended load – Geofencing and Image processing Fixed Asset Damage (external impact) – Alert through PA system, beacon.

- Wrong parking – Conditional alert through text messages to vehicle owner and security in-charge; Automatic number plate detection, track and trace .. etc.

Moving forward, dss+ plans to charter and tailor make the project use cases for all the sites based on the key risks identified, their impact on the client; their probability, severity and ease of implementation using video analytics.